The transfer case in BMW cars may malfunction due to various reasons, and if it breaks down, it can be repaired either independently or by turning to an auto service.

Causes of Failures in BMW Transfer Case

The breakdown of the transfer case in BMW cars may occur due to the following reasons:

- Wear and tear.

If the car owner doesn't remember when the oil was last changed in the SUV, then the problem lies precisely there. The parts of the gearbox simply wear out;

- Seals.

They deteriorate gradually, so the most optimal solution is to purchase a large quantity of them and replace them every 100,000 kilometers;

- Chain.

Chains are consumables. One may wear out, another may stretch. When problems arise, it is advisable to immediately purchase a replacement — the cost of an original one starts from 15 thousand rubles;

- Cheap oils.

According to representatives of the manufacturer, only original oils should be used, as being penny-wise can be pound-foolish. Such oil will no longer lubricate anything, it will just smell.

Statistics show that every 100-150 thousand kilometers, a pump failure occurs in the transfer case. In this light, it makes sense to adhere to the recommendations of car dealerships, suggesting undergoing a technical inspection at least once every 30 thousand kilometers.

If a noise starts to be heard from the transfer case, it indicates wear and tear of the shaft bearing. A significant gap appears in it, which can cause more harm than just replacing the bearings. Checking the servomotor for malfunctions is done by placing the car on a slippery surface. If the front drive does not engage, then the problem lies there.

The pump's operation is often disrupted due to a malfunction of the transfer case servomotor, causing the front axle to always be engaged. Following the pump, the support bearing and support plate break down, being the most in-demand parts when repairing a BMW transfer case.

Ways to Repair a BMW Transfer Case

Repair can be divided into a number of main stages, which remain unchanged regardless of the chosen repair method. These include:

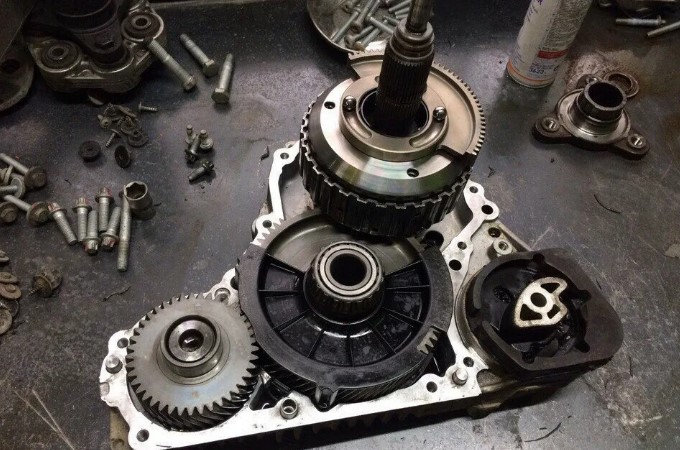

- Disassembly;

- Determination of existing defects;

- Flushing;

- Assembly.

DIY Repair (in a garage)

This method will be the optimal choice for those who are handy and have enough free time. The estimated repair time will take 40 minutes.

It is necessary to identify which specific part has failed in the transfer case, purchase a new one, and insert it into the gearbox. The repair cost will be minimal since both the chain and seals are inexpensive. The only thing required to buy is good oil.

Repairing the Transfer Case in a Service Center

The average cost of restoring the transfer case is 35,000 rubles. To install a new transfer case, double the amount should be spent. The decision on which option to choose is solely up to the owner.

How to Prevent Breakdowns?

To prevent breakdowns, it is necessary to follow the following recommendations:

- More lubrication. In reality, it is better to over-lubricate than under-lubricate. Only original oil should be used, not its Chinese substitutes. It may cost a little more, but there will be no need to open the case every three months;

- There is no need to try to save on the chain — once it slipped off and tore apart all the internal components of the case. The repair cost was 100,000 rubles, while a new good chain cost 15.

Repairing the Transfer Case Servomotor on BMW

The transfer case servomotor is one of the most important components in the construction of the BMW all-wheel-drive transmission. Its task is to engage the front axle when receiving a command from the ABS control unit about the difference in wheel rotation on the rear axle of the car.

A driver will quickly notice that the servomotor of the car has malfunctioned. A considerable number of lamps — 4×4, Brake, DSC, ABS — will light up on the instrument panel. At the same time, they will feel the inability to engage the front axle.

The car will accelerate slowly and get stuck even in small road irregularities. Servomotor failure can also occur when the front axle is engaged. At that moment, the front axle will not disengage, causing a slight increase in fuel consumption and leading to wear of the front differential.

Additionally, there will be crunching and vibration in the transmission during rapid acceleration. To prevent such wear, it is advisable to regularly change the transmission oil every 30,000 kilometers of mileage. Only the original variety for BMW should be used.

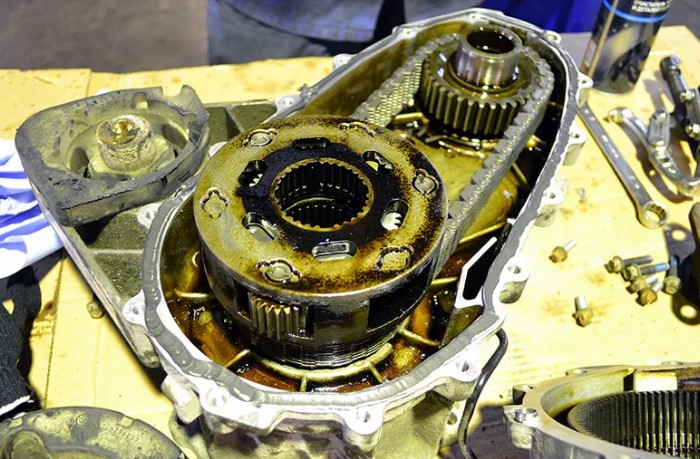

The main cause of breakdown is often a faulty Hall sensor. This results in incorrect servomotor operation. As a result, the plastic gear will wear out, and the gear shaft will bend.

Servomotor Repair

The standard repair procedure involves replacing the plastic gear. When replacing it, the transmission oil should also be changed, and the adaptation in the control unit should be reset. If metallic shavings are found in the oil, then the entire gearbox will need to be repaired.

NEVER turn the gear, as cutting its edges helps prevent the entire gearbox from breaking down. During repair, only plastic gears should be used, and the Hall sensor must be replaced as a mandatory step.

The transfer case does not break down on its own (exception being rare cases of factory defects) but does so only due to the servo motor responsible for its engagement. There are several types of malfunctions, but they are all related to the Hall sensor. In increasing order of severity, such breakdown scenarios can be named:

- The servo motor is not working, and the 4×4 error light is on the instrument panel. This indicates that the car is moving exclusively on the rear differential, and front engagement is not possible. This is the simplest breakdown, requiring only servo motor repair. The servo motor gear also gets damaged here;

- The transfer case is engaged permanently, simultaneously with the servo motor, which does not disengage it. This leads to constant front axle operation, accelerated wear of friction components, chain stretching, bearing failure due to abrasive particles;

- The worst scenario is non-engagement of the transfer case by the servo motor, with a stop somewhere in the middle. In such a situation, the transfer case is usually discarded, and the repair costs a pretty penny. All bearings, chain, frictions, and one of the upper gears must be replaced because the gear edge under the retaining ring is torn off. The servo motor will definitely have faulty gear and Hall sensor.

All major problems in the transfer case start with the servo motor that engages the front axle in case of wheel slippage.