Exquisite Valve Solutions by BMW Engineers

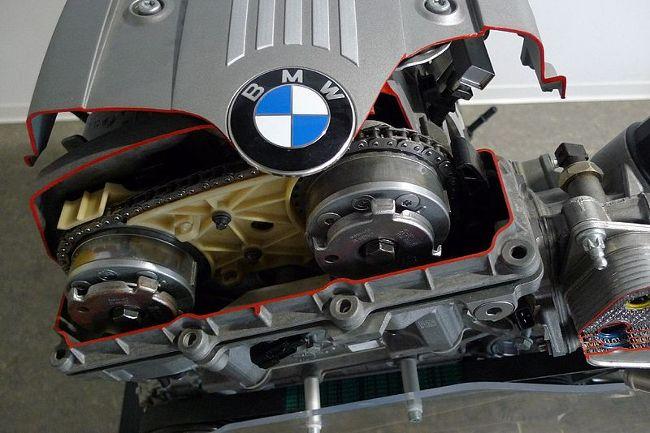

To enable controlled distribution shaft management by altering the gas distribution in the engine, the engineers at Bavarian Motor Works (commonly known as BMW) have devised a solution — a special vanos valve, derived from the German variable Nockenwellensteuerung.

Function and Types of VANOS Valve

This device is located directly in the engine and comes in two types — single-piston for intake valves and dual-piston for both intake and exhaust. This technology was first introduced in 1992 and has only been improving with each passing year.

The seamless operation of the vanos valve provides the vehicle with smooth idle, «soft» power delivery, and optimal torque distribution. The «side» effects of the equipment's operation include reduced fuel consumption and volumes of nitrogen oxides and carbon in the exhaust gases, fully unleashing the engine's power potential.

VANOS Valve, Common Malfunctions

In general, the vanos valve in BMW is a reliable mechanism, although its components are susceptible to wear and tear. The weak point of the device lies in the seals and bearings. Let's explore the most common breakdowns.

- A malfunction manifests in the delayed start of the Vanos valve and subsequent disconnection. This issue is related to the expiration of the warranty period for the sealing rings after exceeding the mark of 50 thousand km on the odometer. The seal material does not withstand aggressive environments (severe frost, sharp temperature fluctuations), leading to deterioration and compromising the mechanism's seal. BMW does not produce special repair kits, so finding replacements for the seals will have to be done independently.

- During engine operation, knocking and rattling noises are audible — indicative of worn needle bearings of the valve. Simply replacing these elements with new ones completely resolves the issue.

- The jamming of the vanos valve mechanisms, resulting in the complete shutdown of the system. The cause of the problem often lies in the formation of microcracks and burrs on the flange of the distribution shaft. Normal grinding with fine-grit sandpaper of the affected element eliminates the malfunction.

- In the newer models of BMW, an electromagnetic vanos valve is utilized. Failures in such a mechanism manifest in reduced power parameters, idle uniformity issues, or strange sounds. The cause may lie in the appearance of irregularities on the piston edge or a break in the valve cable's supply. Grinding or replacing the part in the former case and restoring the wiring in the latter completely resolve the problem.

Advice for BMW Owners

If there is a distinct and persistent knocking under the hood, noticeable engine power loss, and idle issues, dismantling and inspecting the vanos valve will be necessary. Any driver can accomplish this task with a standard set of tools.

You can assess the level of wear by simply depressing the control piston. If it smoothly sinks and is pushed back by the spring, replacing the sealing rings will suffice.

Otherwise, the element itself and the cylinder will require sanding or complete replacement of the moving part. Troubleshooting an electromagnetic vanos valve should begin with checking the integrity of the wiring. Often, restoring the wiring is a sufficient solution.

Consequences of Neglecting VANOS Valve Repair

Driving with a faulty vanos valve is possible, but it will lead to the following issues:

- Unstable engine start and vibration at idle;

- Spark plug fouling;

- Low power output with increased fuel consumption.

Hence, delaying the mechanism's repair is not advisable under any circumstances. A functional vanos valve is the key to a comfortable driving experience.