From the owners of BMW, especially the E39 and E53 models, complaints are often heard that the engine starts to overheat during the operation of the air conditioner, especially in high temperatures and traffic jams. There can be several reasons for the breakdown that leads to further repairs of the BMW air conditioner.

Causes of BMW Air Conditioner Breakdowns

The most common malfunction is the failure of the air conditioner fan. This is a serious issue, as when it occurs, the air conditioner cannot function properly. It is possible to drive with a malfunctioning device, but there is no guarantee that you won't have to repair the air conditioner itself or even the entire engine system.

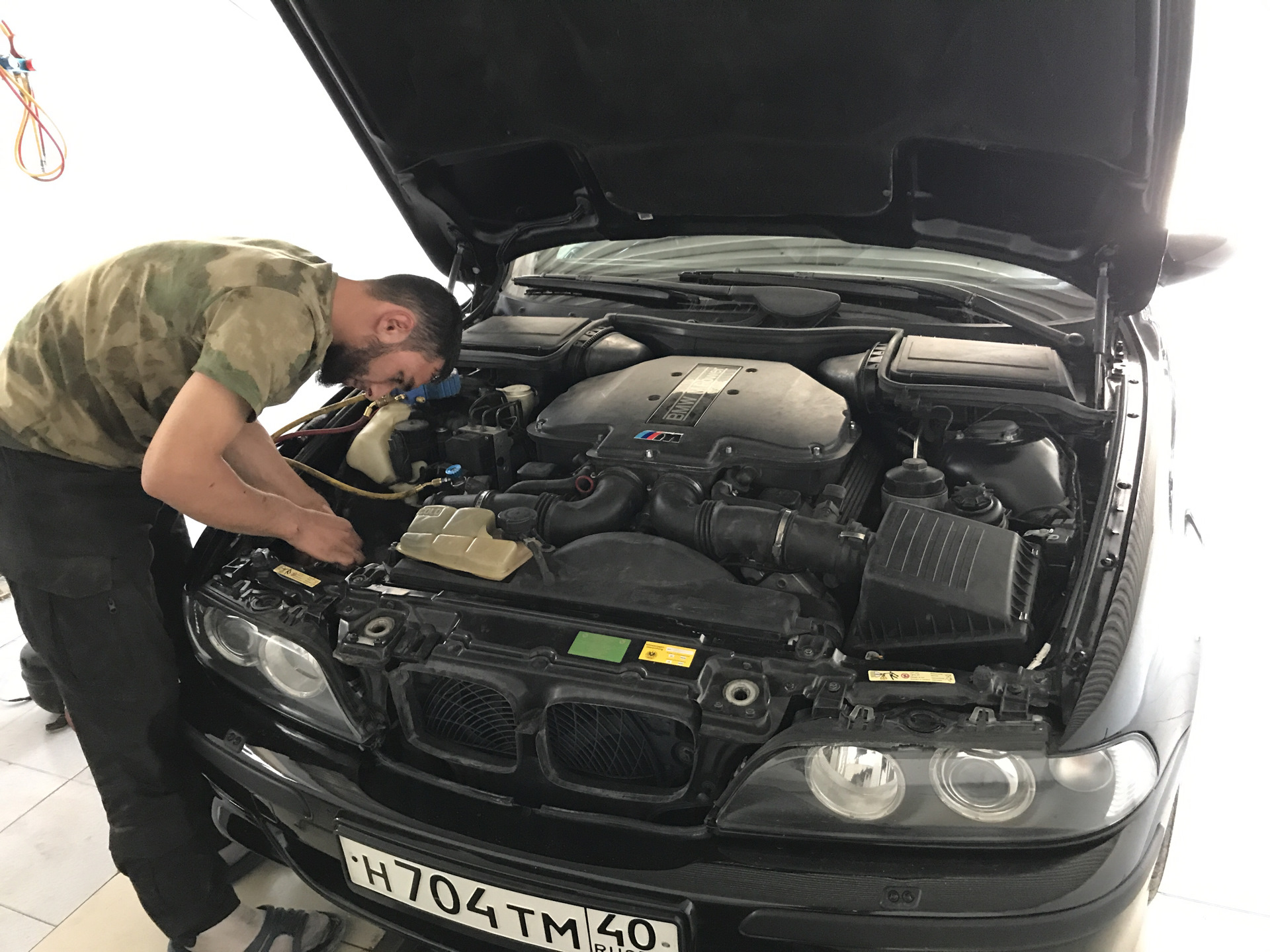

Fixing such a breakdown on your own is not the most optimal solution, especially in cars that have undergone restyling. However, among fans of German cars, there are craftsmen with experience in repairing such devices in garage conditions.

During operation in Russia, car air conditioners often fail due to sharp temperature changes. The device simply may not withstand increased loads at temperatures as low as -40 degrees and the same with a plus sign in the summer.

Most often, for the fan motor to wear out completely, it takes about 3-4 years for outdated models. If such a malfunction occurs in a new car, then it is a defect.

What Could Be the Malfunctions?

Before starting the repair, it is important to determine the possible breakdowns. These may include:

- Output cascade of the fan;

- Fan relay;

- Fan motor;

- Power supply;

- Output of control voltage.

Strength Tests

First and foremost, it is important to check the operation of the motor itself. For this, a voltage of 12V is applied to it, with the connection of blue and brown wires that connect the board and the motor. A third wire will be necessary to control the negative of the relay.

If everything works, then the driver is lucky – it will just be necessary to search for and replace other parts. If the motor does not start, then a new one should be purchased, which requires much greater expenses.

If the required car accessories are available, the repair will take about 2 hours. Experienced specialists advise consulting first with an experienced auto electrician, given the decline in the quality of BMW licensed parts being produced.

Repairing the BMW Compressor

The air conditioning system in BMW cars is responsible for the comfort level of the driver and passengers. Thanks to its presence, they can feel comfortable in the car during hot weather. One of the main devices of this system is the compressor, which is responsible for circulating the refrigerant in the system. It can be said with confidence that without the compressor, the system simply cannot function.

The operation of this system is very simple. With the BMW compressor, freon is pumped into the radiator, where the gas is cooled and turned into liquid under the influence of the fan. If there is an insufficient or excess amount of gas, it creates additional loads on the BMW compressor, accelerating the wear of its components.

In this light, regular technical maintenance becomes very important, during which attention must also be paid to the BMW car air conditioner.

Main Signs of Compressor Malfunction

The following malfunctions of the air conditioning system have become most widespread:

- Insufficient cold air in the cabin and the appearance of leaks, which is a sign of a compromised system;

- Appearance of strange noises, indicating wear of the compressor valves and pistons.

If we are talking about BMW compressor repair, it primarily involves analyzing its working elements from a technical point of view. First, the refrigerant level is checked with a diagnostic device.

Subsequently, the compressor is disassembled, and each of its components is evaluated for quality and performance. The most common repair actions for the BMW car compressor include the need to replace the bearing, electromagnetic valve, thrust plate, or piston group.

It is worth noting separately that repairing the BMW compressor will be significantly cheaper than purchasing a new one. The process of repairing the compressor itself is quite complex – it requires specific experience, special tools, and equipment.

One should not forget about the harmfulness of the chemical composition of the refrigerant gas, with which one will inevitably have to deal during the repair process. This gas can have a negative effect on the skin and cause burns. Therefore, it is strongly not recommended to perform BMW compressor repair work.

Replacing the BMW Air Conditioner Belt

In the design of certain engine modifications, one of two types of tensioners is provided – mechanical or hydraulic.

A drive ribbed belt with automatic tensioning is used to drive the compressor.

Before removing the belt, it is important to mark the direction in which it rotates with a marker-drawn arrow if you plan to reuse it. The belt must be installed back in accordance with the marking.

If there are contaminants from coolant, hydraulic system fluid, or oil on the belt, it needs to be replaced. For the ribbed drive belt, replacement is carried out under the following circumstances:

- Presence of contaminants from coolant or oil;

- Appearance of belt slipping noise due to oiling or stretching;

- Formation of cracks and brittleness;

- Breakage of the carcass or individual strands;

- Fraying and wear on the side surface.

Replacing the compressor drive belt with a hydraulic tensioner is done as follows. First, remove the protective cover of the hydraulic device. Loosen the tension of the compressor drive by installing a socket wrench with a hex head on the tension roller bolt.

The key should be slowly turned clockwise to release the hydraulic tensioner from the belt and allow removal of the compressor drive belt.

To install the belt, fully press the tensioner to the right and install the new belt according to the layout. Be sure to ensure that the belt fits snugly into the pulley grooves.

If the device has a mechanical tensioner, it will be necessary to release the tension roller by turning the socket wrench in the internal hexagon and remove the drive belt. When installing a new belt, the tension roller will automatically set the tension. The tension force of the roller cannot be adjusted. It is also necessary to ensure the correct tension of the belt on the pulleys.